Published on:

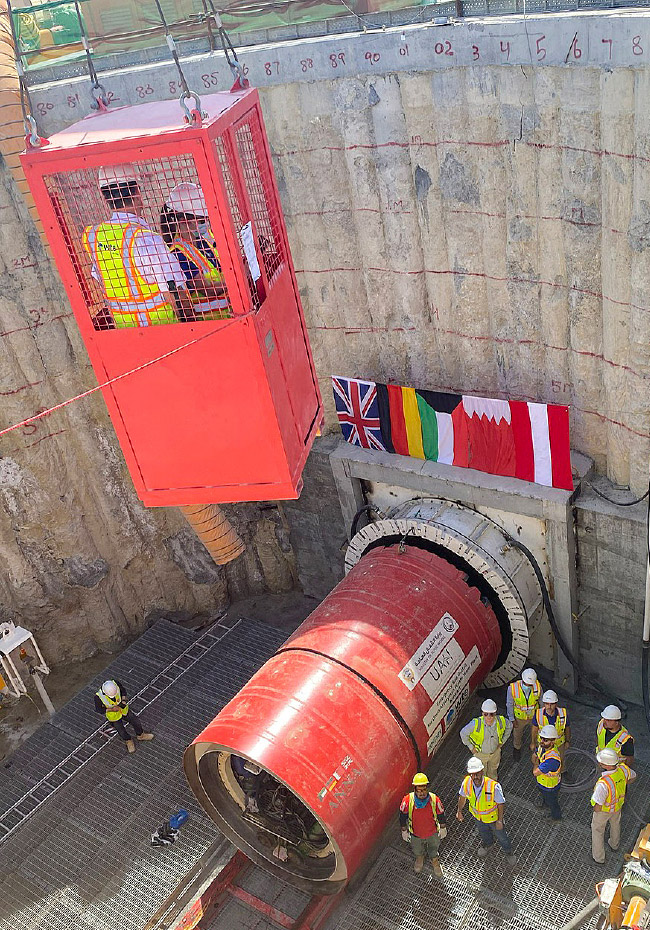

The first tunnel boring machine for the emergency sea outfall was ceremoniously brought into the launch pit.

In Umm Al Hayman, one of the world’s largest wastewater projects is being built to dispose of wastewater from the south of Kuwait and to supply agriculture and industry with process water. WTE supplies a complete package from wastewater collection to treatment in a state-of-the-art wastewater treatment plant and subsequent distribution all the way to energy generation, composting and plant operation – as a one-stop solution.

Normally, all the water treated to the highest quality standards will be used for irrigation in agriculture, or as process water in industry. In exceptional cases where the demand for water is less than the amount produced, the excess treated water must be discharged to the sea via the emergency sea outfall. For this purpose, a drainpipe with a total length of approx. 5.5 km is to be laid. From the outlet of the wastewater treatment plant to the coast, an approx. 1.5 km long section will be laid using the microtunnelling method. This work started in mid-September 2021.

The remaining section is being constructed using the cut-and-cover method; more than 2 km of this section has already been completed.

In a few weeks, the second tunnel boring machine will also begin its 2 km long journey under the seabed.

This important sub-project combines German engineering and German mechanical engineering know-how, for the tunnel boring machines are also “Made in Germany”.

With the completion of the entire project, we will make an important contribution to the sustainable development of Kuwait.

Key data of the emergency sea outfall

Onshore: L approx. 3,500 m; DN 2,400 of which approx. 1.5 km as microtunneling

Offshore: L approx. 2,000 m; DN 2,200 (offshore microtunnelling)

06/02/2015

Ground-breaking ceremony in Tivat-Kotor05/28/2020

Handover of the wastewater treatment plant Tivat-Kotor / Montenegro11/03/2014

Agreement on the sale of the sodium hypochlorite plant, Moscow09/23/2019

WTE and EU invest in Croatian pearl Varaždin10/18/2021

300 KV transformers on the way to Umm Al Hayman04/13/2016

WTE at IFAT 30.05. – 03.06.2016