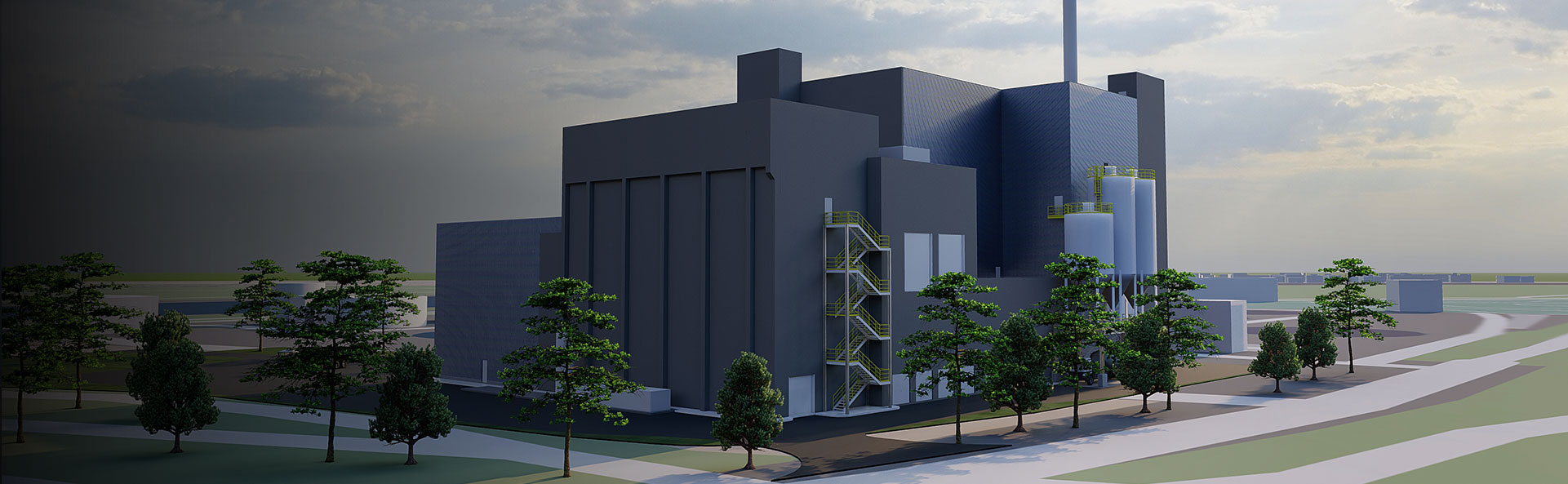

With WTE, the construction of water and wastewater plants for municipalities and industry can be implemented smoothly and professionally.

Professional construction of water and wastewater plants is especially important for municipalities and numerous branches of industry. All the requirements from the call for tenders and all the legal specifications that were taken into account in the plant design process need to be implemented structurally with all processes meshing together seamlessly.

For this reason, it pays to work with a strong partner from the outset. The WTE Group specialises in the construction of plants for water and sludge disposal infrastructure. With our specialist expertise, we make every construction project a success. Discover the economically sound and ecologically sustainable plants implemented by the WTE Group.

How can the world of tomorrow survive with nature remaining unspoiled and healthy – and what can we do as a company to contribute to this actively and responsibly?

We build on sustainability – consistently.

In more than 30 years of operating as a general contractor, we have adapted our range of services to suit our customers’ needs today and the requirements of the generations of tomorrow. We already successfully set up technical plants in the fields of drinking water, wastewater and sewage sludge utilisation all over the world.

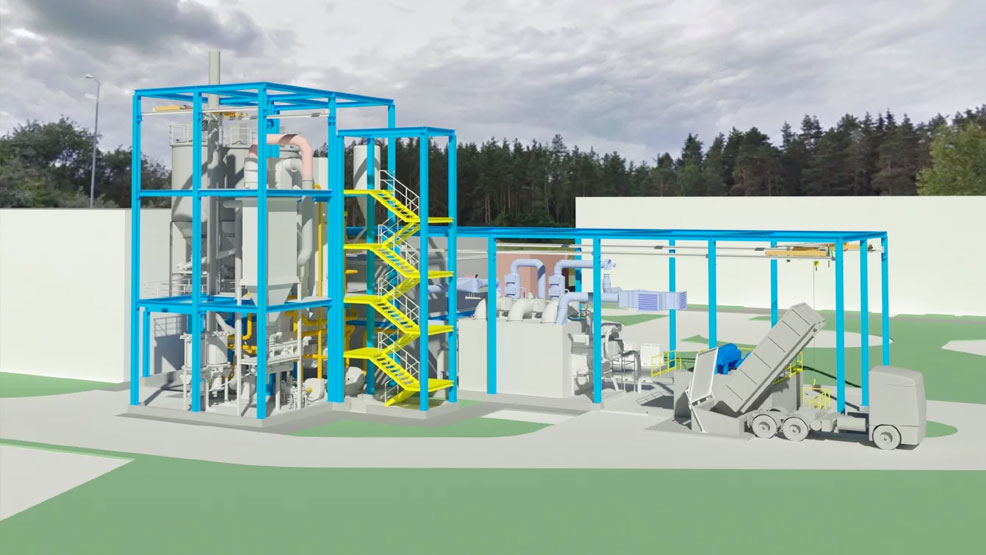

Together with our experienced partners, we realise the turnkey construction of new plants or fully update existing plants by means of modernisation and implementing additional purification processes. We use environmentally friendly and standardised construction methods, configure plants to use low-emission operational workflows and incorporate ways to produce renewable energy in every project.

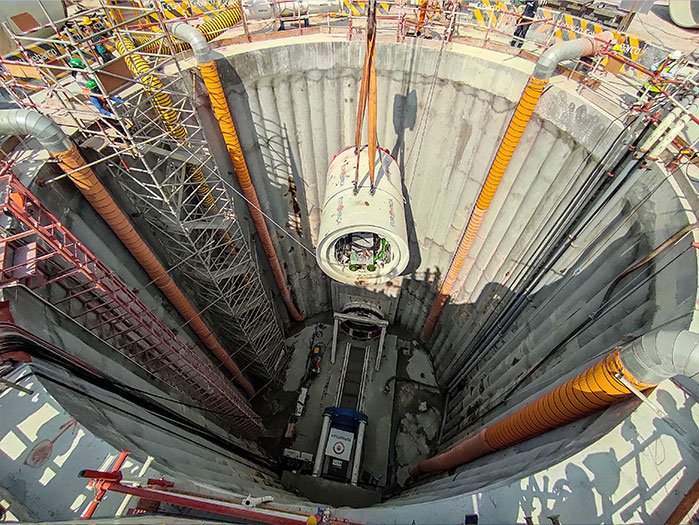

No two projects are ever the same – and our plants are no exception. Erecting complex and custom technical buildings on behalf of our customers is our passion and our goal.

Tim Kerstein, WTE Wassertechnik GmbH, Technical Project Director, Umm Al Hayman project

The requirements for plants used to treat drinking water, wastewater and sewage sludge keep on evolving. This makes it all the more important to use solutions in plant construction that utilise forward-looking concepts and technologies today. These high expectations when it comes to quality are reflected in all the water, wastewater and sewage sludge utilisation plants of the WTE Group – in new buildings and in refurbishment and modernisation. Custom, sustainable and future-proof structural solutions are what we promise our customers.

All technical components are combined to form an overall system with clearly defined tasks, in order to ultimately realise a plant that not only satisfies customers but also constantly ensures environmental protection by complying with the legal specifications for the process parameters. To achieve this, all the required specialist technical areas are firmly integrated into our plant construction, such as process engineering, mechanical engineering and electrical engineering, but also civil engineering, energy technology, design and logistics.

Our projects involve experienced and multidisciplinary teams that have garnered extensive experience across all service phases, from approval planning to structural implementation and commissioning.

Maximum purification performance with cutting-edge process technology, low space requirements – over 30 years of industry knowledge, an eagerness to learn and a commitment to quality are combined in our plant construction. The end result of the process is a range of custom solutions for our customers all over the world. Take a look at some of the projects we have already realised on our references page

If you have any questions or concerns, we are happy to help – simply get in touch.

If you review, question and optimise your own processes and initiate improvements, you can achieve long-term success. Adjusting the respective work procedures, specifying responsibilities and accountabilities and regulating workflows within the company makes it possible to implement plant construction projects on schedule. Fixed structures and standards guarantee efficiency and work of consistently good quality. By incorporating management and quality assurance systems into our day-to-day work, we give our customers, business partners and suppliers confidence in our collaborative work.

Sustainability is one of the WTE Group’s guiding principles. This is why our construction work is consistently sustainable – we use environmentally friendly and standardised construction methods, configure plants to use low-emission operational workflows and incorporate ways to produce renewable energy in every project. Focusing on closed-loop systems and sustainable energy generation enables fully energy-self-sufficient operation, in new plants as in upgrades. This increases plant efficiency, reduces emissions and operating resources and guarantees economical operation for our customers.

The structural realisation of a plant that has come together in close coordination with the customer is always a special achievement. We are creating something of great significance – for our customers, for large numbers of people and for the ecosystem.

Dr.-Ing. Ralf Schröder, WTE Wassertechnik GmbH, Spokesman of the Management Board

Wastewater treatment and sewage sludge incineration, Tubli, Bahrain

View reference

Czajka Wastewater Treatment, Warsaw, Poland

View reference

Sewage sludge incineration, Berlin-Waßmannsdorf, Germany

View reference

Sewage sludge mono-incineration Hannover-Lahe/Germany

View reference

Drinking water treatment plant Gilau, Romania

View reference

Sewage sludge incineration Utena/Lithuania

View referencePhone: +49 201 8968 500

Email: info@wte.de