Thermal sewage sludge utilisation

for municipalities and industry.

The thermal utilisation / mono-incineration of sewage sludge is a reliable, tried-and-tested method for disposing of the excess sludge produced by wastewater treatment plants. The sludge is a product of the wastewater treatment process and must be disposed of correctly in accordance with AbfKlärV (Germany’s Sewage Sludge Ordinance). With the amendment of the Sewage Sludge Ordinance, there will be a fundamental change in the disposal options that are permitted for sewage sludge producers in Germany: for many operators, the land application will no longer be allowed as a disposal method. The WTE Group uses its knowhow to support municipalities and industry in safely and efficiently disposing of sewage sludge using the mono-incineration method.

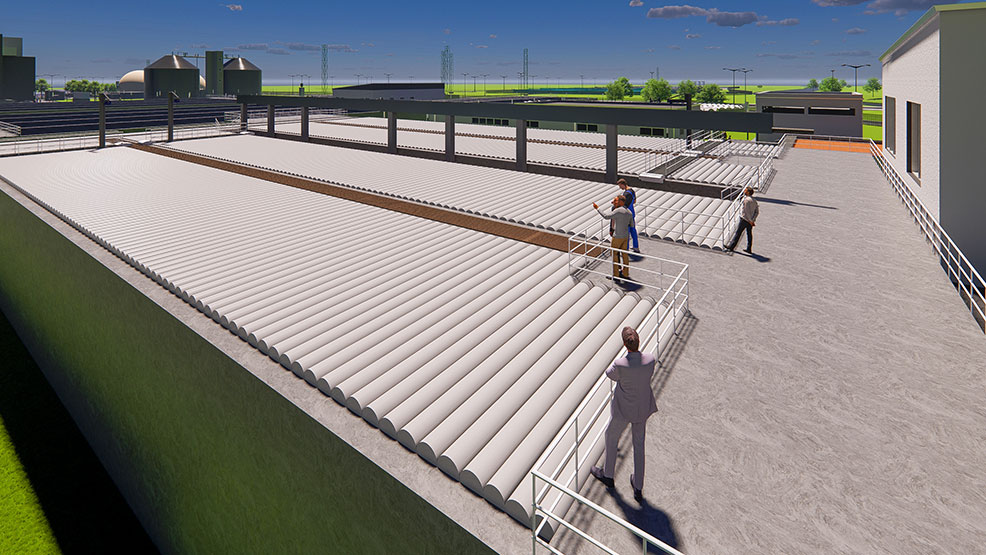

For the utilisation of sewage sludge, we use energy-self-sufficient processes that are planned in detail and that meet the latest technical standards. The resource-conserving and sustainable method is also highly flexible: from the turnkey sewage sludge plant to the custom-planned, decentralised solution on site, we work with our customers to select the best option for humankind and for the environment.

With our expertise in plant construction, we understand that sewage sludge has a lot of potential. Our plants are designed to make use of the energy and the raw materials that the sludge contains and to use treatment methods that maximise recovery. In line with this philosophy, we design and realise custom plants for thermal sewage sludge utilisation that meet the highest demands for disposal safety, emission reduction, sustainability and energy efficiency. This enables valuable resources to be conserved and costs for disposal to be lowered.

Utilising municipal and industrial sewage sludge appropriately calls for cutting-edge technology and sophisticated processes. The solutions of the WTE Group combine sustainability and cost-effectiveness under one roof – in the interests of our customers.

Jörg Huffschmid, WTE Wassertechnik GmbH, Head of Tenders, Sewage Sludge

Download

WTE Sustainability Report 2022

When we design plants for sewage sludge utilisation, we always concentrate on the individual requirements of each project. This results in a custom utilisation plant with a modular design that offers standardised high quality levels while satisfying tomorrow’s legal requirements today.

We use the thermal energy released when sewage sludge is incinerated to generate electrical energy in turbine systems and to feed it back into the process in order to dry the sludge, thereby ensuring autothermal incineration. This allows us to make optimal use of the sludge’s energy potential. All plants are dimensioned with the aim of enabling self-sufficient supply with electrical energy. It is also possible to incorporate excess heat into a district heat system.

The dry sewage sludge mass is incinerated in a fluidised bed furnace at temperatures of roughly 850 °C – 950 °C. The high temperatures inside the sewage sludge mono-incineration plant ensure safe and low-pollutant burnout of the fuel, with excess heat fed back into the system and/or fed into the public grid. The amount of ash and residues left behind at the end of the process corresponds to only roughly 10% of the original mass of the sewage sludge to be disposed. Water vapour generated in the process is fed to turbines or additional plant modules (CHP plants) specifically for the purpose of generating electricity.

As WTE Group, we design custom plant concepts precisely as needed, with and for our customers. We develop plants for sewage sludge utilisation for wastewater treatment plants of all sizes, for municipalities and associations in Germany and abroad. View our references for an initial impression of the projects we have realised domestically and abroad. Would you like to find out more about our expertise and services? Then get in touch with us for one-to-one consultation.

By 2029 at the latest, stricter regulations will apply for the operators of wastewater treatment and sewage sludge incineration plants in Germany, especially with regard to the recovery of phosphorus from sewage sludge. With our partners, we put together groundbreaking concepts for carefully separating the raw material phosphorus from the sewage sludge after the thermal utilisation and efficiently preparing it for reuse. This means that the phosphorus can remain in the resource cycle. Our guiding principles in this context are:

The recovery of phosphorus is set to be an important challenge in the future – we are working on finding suitable solutions today.

Franz-Josef Kramer, WTE Wassertechnik GmbH, Head of Plant Design Sludge Department

While sewage sludge incineration is currently a common method for utilising sewage sludge in Germany, we also have experience in plant construction for corresponding technical alternatives. We have set up systems in various projects worldwide for anaerobic digestion with downstream composting or solar drying of sewage sludge.

In composting systems with tailored dimensions, sewage sludge can be processed for use in agriculture or road construction in accordance with national regulations.

We therefore provide a custom concept for every plant, from new builds to existing facilities, that ensures complete and sustainable sewage sludge utilisation, adapted to suit the local rules and regulations – both in Germany and in our international projects. With our local partners on site, we develop solutions that ensure optimal disposal channels for our customers’ specific processes.

The WTE Group is your partner for professional sewage sludge incineration with legal certainty. Our plants are designed exactly in line with customer requirements, with the greatest possible efficiency. We use smart closed-loop circulation to create strong synergies and conserve natural resources while lowering all costs relating to the utilisation.

We can realise your custom-dimensioned incineration plants with a fully decentralised design to meet your needs. The sewage sludge will then be incinerated in the direct vicinity of where it is generated.

We will gladly realise your plant as general contractor. In this role, we take care of all steps in the project for industry and for municipalities: we supply conception, design, optional financing and plant construction all from a single source. We can also perform the entire operational management, as part of a long-term partnership if desired.

Sewage sludge incineration, Berlin-Waßmannsdorf, Germany

View reference

Sewage sludge mono-incineration Hannover-Lahe/Germany

View reference

Wastewater treatment and sewage sludge incineration, Skopje, North Macedonia

View referencePhone: +49 201 8968 500

Email: info@wte.de