Berliner Wasserbetriebe (BWB) operates six treatment plants in Berlin and in the surrounding area. These plants purify the wastewater produced by Berlin and roughly 30% of the wastewater produced by state of Brandenburg. At present, roughly 60% of the sewage sludge created is utilised in the company’s own sewage sludge incineration plant at the Berlin-Ruhleben site. The rest is co-incinerated in external power plants and cement plants.

In response to the amendment of Germany’s Sewage Sludge Ordinance (AbfKlärV), the Berliner Wasserbetriebe have opted for a sewage sludge disposal strategy that involves abandoning external co-incineration and transitioning to 100% internal thermal utilisation. Consequently, the Ruhleben incineration plant will continue operation and be supplemented by a new sewage sludge utilisation plant at the Waßmannsdorf site to secure profitable disposal security in the future.

64,000 t DM/a

sewage sludge

4,000 t DM/a

screenings

30 MW

fuel heat output

Following a market survey, competitive bidding and the call for tenders based on a preliminary design with functional performance description, the WTE emerged a winner in the tendering procedure in a consortium with the WTE Betriebsgesellschaft. The contract for the design, construction and commissioning of the fully functional and approvable overall plant, in turnkey and ready-for-operation state, was awarded in May 2020. The assignment is split up into three sub-assignments.

The contract has a term of five years and ends with the start of regular operation in 2025.

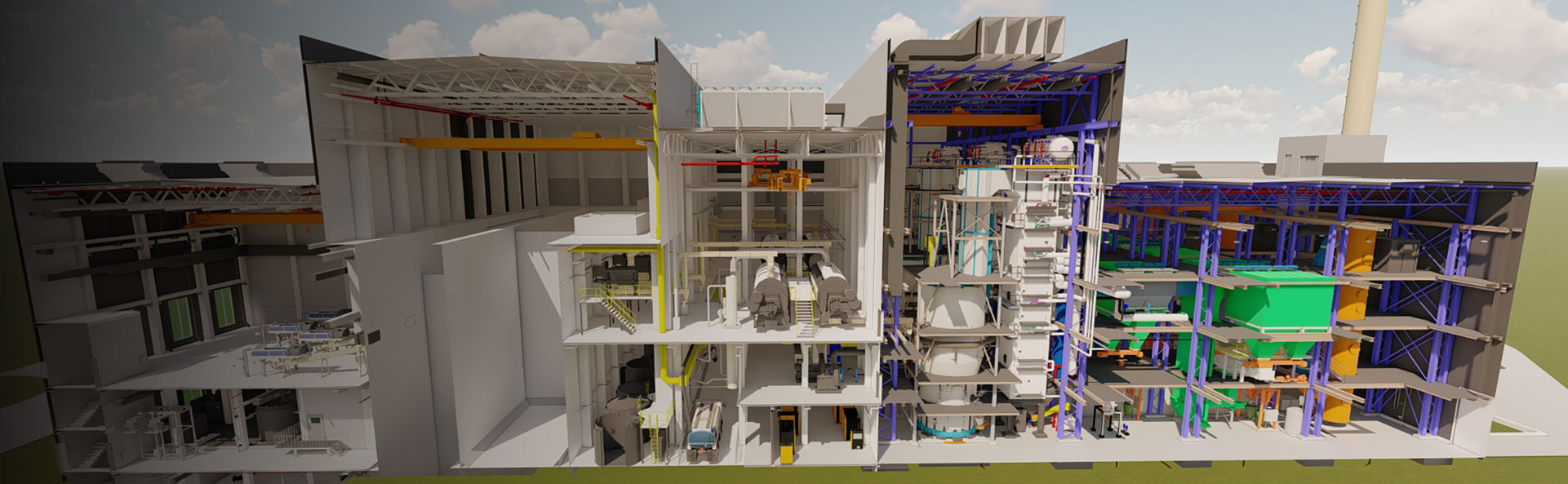

The new sewage sludge utilisation plant has a future-proof design. This includes the configuration to the planning horizon of 2040 with a sewage sludge volume of 64,000 t DM/a plus 4,000 t DM/a screenings, but also the modular structure of the plant with three lines operating separately. The spatial planning at the Waßmannsdorf site also provides for an additional line being added to the plant as needed in the future. With equal vision for the future, space has been reserved at the site for optional phosphorus recycling to be added later.

This is perfect for an autonomous solution, as it provides the maximum amount of flexibility given the coming obligation to recover phosphorus. The phosphorus concentrated in the incineration ash can also be returned to external utilisation, if internal treatment is decided against in the future.

Find out more about the sustainability aspects of the project:

Download

WTE Sustainability Report 2024In addition to the future-oriented utilisation concept, the planned heat recovery will secure sustainable heat utilisation not only on site. The excess heat will also be fed into the district heating grid.

The vapours generated by the drying process are treated at the plant and fed back to the treatment plant as purified condensate. At the end of the value chain of the vapour treatment, a substance has been recovered that can be used as a fertiliser.

Even during the plant’s engineering phase, the plant’s overall energy efficiency is given top priority. For example, a high-efficiency reaction turbine is used that not only makes the utilisation plant energy-self-sufficient but also makes a significant contribution to the energy self-sufficiency of the Waßmannsdorf treatment plant.

Phone: +49 201 8968 500

Email: info@wte.de